Textile Instruments / TEXTECHNO

STATIMAT 4U

Automatic Linear Density and Tensile Tester for High-Tenacity Yarns

STATIMAT 4U is an automatic tensile- and linear-density tester for very coarse and high-tenacity yarns with a force measuring range up to 5.000 N. Special features like heavy-duty clamps with automatically operated force reduction cams and a rotary clamp to apply a twist to the yarn prior to tensile testing make the STATIMAT 4U unique in the field of automatic tensile testing of threads. STATIMAT 4U is suitable to test even Aramid and high-tenacity Polyethylene (UHMWPE) yarns. A further application is twist-testing of threads.

Automatic Linear Density and Tensile Tester for High-Tenacity Yarns STATIMAT 4U

Automatic tensile tests on yarns with high linear density and breaking strength demand special requirements regarding clamps, measuring system, sample waste disposal, and mechanical stability of the testing equipment. This particularly applies to technical yarns comprising high-tenacity polymers such as Aramid or UHMWPE.

Here force-measurement limits of 1000 N and mechanical stress limitations for such test equipment are insuffi cient in most cases. In addition, the clamps of the automatic tensile testing equipment are often inadequate for withstanding breaking forces of this magnitude.

Moreover, for untwisted technical fi lament yarns, there is a demand to insert a certain amount of twist into the yarn prior to the tensile test. Compared with tests carried out on untwisted yarns, this method has the following advantages:

- Better definition of the test and lower deviations for breaking-force, elongation at break and work to rupture: During the testing of an untwisted multi-fi lament yarn, usually fi lament breaks occur one after another, whereas a twisted multi-fi la- ment yarn will break suddenly.

- Close-to-practice tests: For most technical yarn applications, the yarn is twisted before being processed and subjected to use in its application.

- Standardized test method: Various standards recommend or require tensile tests on technical yarns to be carried out after twist insertion, e.g. ASTM D 885, Note 9, ASTM D 2256, BISFA standards for Polyester- and Polyamide filament yarns, ISO 2062.

- Possibility for twist optimisation: Material properties which can be measured with the equipment such as tenacity and elongation, work to rupture, modulus, and reference values for force and elongation can be examined regarding the influence of twist. This enables determination of the optimum twist level for respective applications

Application of twist prior to the tensile test

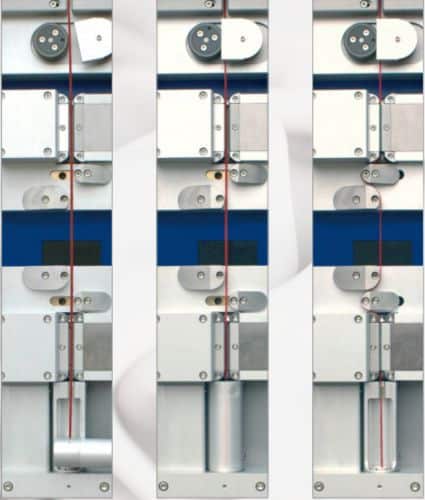

The automatic testing equipment STATIMAT 4U features innovative technical details that take into account the special requirements of technical filament yarns. Both the mechanical construction of the equipment and its force-measuring range are suitable for maximum forces up to 5000 N.

It is equipped with patented bollards located at both clamps (force-reduction cams), which automatically swing in. The clamps are characterised by their outstanding clamping effect. A patented automatic rotary clamp, which is integrated into the test section, inserts twist or changes the twist level prior to commencement of the tensile test.

Determination of the yarn twist

A further and innovative function of the automatic rotary clamp is the optional automatic determination of the yarn twist. In addition to the classical automatic twist test on spun yarn according to the un- and re-twisting method, filament- and plied yarns can now be tested in fully automatic way, too, under certain conditions. The test method can be combined with automatic tensile and / or count testing for maximum testing efficiency.

AUTOCOUNT

For fully automatic yarn linear density measurements the STATIMAT 4U can be fitted with the AUTOCOUNT system. This consists essentially of a yarn collecting chamber and an electronic balance. Here the nip roll feed system measures the length precisely and feeds a yarn length into the AUTOCOUNT collecting chamber.

The yarn linear density is determined on the basis of the weight and the length of the yarn sample.

Additional clamps

In addition to standard tensile tests carried out on yarns, the STATIMAT 4U can also be used within the permissible force range of 5.000 N to carry out tensile- and elasticity tests on fabrics and cohesion tests on slivers and rovings. For this, various special clamps for manual introduction of the test sample are available as replacements for the automatic yarn clamps.

Especially the combination of automatic yarn testing with fabric testing makes this instrument very interesting for weaving- and knitting mills, allowing the automatic checking of the incoming yarn material as well as the quality control of the end product.

Narrow tapes, artificial grass, and monofilaments

New fields of automatic tensile testing have been opened by the development of a mechanical clearing of the yarn remnants after breakage. With this feature the STATIMAT 4U allows fully-automatic tensile tests of monofilaments with diameters up to 1 mm, sticky and very coarse yarns, e.g. waxed sewing threads, as well as narrow tapes, split yarns, etc. for the production of artificial grass.

System Components

Test section: 2 pneumatic yarn clamps with force reduction cams, automatic linear threading by auxiliary clamp, min. gauge length 40 mm, max. travel of draw-off clamp 880 mm for a 100 mm gauge length.

Package changer: Standard version with 24 positions, expandable to 48 positions.

Measuring systems:

- Force-measuring device with easily exchangeable force transducers, max. 5000 N

- Elongation-measuring device with resolver, resolution 0.4 µm.

Twist insertion and determination:

- Rotating auxiliary clamp situated below the draw-off clamp.

- Untwisting for plied yarns, threads, and multi-filament yarns.

Yarn feed mechanism: Nip-roller system, max. yarn delivery speed of 300 m/min, resolution of length measurement 0.3 mm.

AUTOCOUNT: Yarn collection- and weighing device, measuring range 0 – 310 g, resolution 1 mg.

Further technical data

- Mains supply : 230 V, 50 (60) Hz, current

requirement approx. 1 A - Compressed-air supply: min. 5 bar, 150 l/min (with

- AUTOCOUNT: 200 l/min)

- Lacquer finish: RAL 9006/5002

- Dimensions: Height 1850 mm, Width 910 mm (for 24 position package changer), Depth 700 mm

- Weight: approx. 290 kg.

The above information can be subject to changes by Textechno.

Application fields for STATIMAT 4U

- FILAMENT YARNS

- SPINNING MILLS

- FABRICS