Evaluating an extensive array of fiber properties is imperative for conducting research and ensuring quality control in the production of man-made fibers, as well as for evaluating the feasibility of fiber processing during carding and spinning.

These tests involve the examination of individual fibers, both for man-made and, in certain instances, natural fibers. In this context, common testing procedures include conducting static tensile tests, measuring linear density (fineness), and assessing aspects such as crimp extension, crimp stability, and crimp count.

Single-Fibre Testers

Parameters |

Recommended Testing Instruments |

| Tensile properties | FAVIGRAPH, FAVIMAT+ with either ROBOT 2 or AUTOFEED |

| Linear density | FAVIGRAPH, FAVIMAT+ |

| Crimp geometry, mechanical crimp, friction, bending stiffness | FAVIMAT+ |

| Resistance to bending/abrasion and alternating stress | FIBRESTRESS |

| Comprehensive assessment of all relevant fibre material properties | Supply of complete testing laboratories, installation and consulting by Textechno experts |

Automatic Single-Fibre Tester

FAVIGRAPH

TEXTECHNO offers a solution for clients in need of a rapid tester for single-fiber linear density and tensile measurements, which is the FAVIGRAPH. This system positions the linear density measuring head next to the tensile test section. Upon determining linear density, an automated transfer clamp shifts the fiber to the tensile test area and positions it within the measuring and draw-off clamps. Consequently, the operator is only required to manually insert the fiber once to conduct both tests. This design allows for simultaneous testing of the next fiber at the linear density measuring head during tensile testing, thereby enhancing operational efficiency.

Moreover, as an additional feature, the FAVIGRAPH can be outfitted with short-fiber clamps, enabling the testing of fibers with lengths as short as 3 mm.

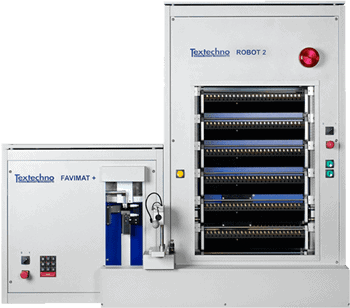

Automatic Single-Fibre Test System FAVIMAT+

FAVIMAT+ is worldwide the first and only single fibre tester which combines six test methods in one instrument, for the determination of the following fibre properties:

- Linear density

- Tensile properties

- Mechanical crimp properties (percent crimp, crimp removal force and crimp stability)

- Geometrical crimp structure

- Fibre-to-metal friction

- Bending stiffness

Operation of the FAVIMAT+ can be fully automated by means of the optional infeed systems ROBOT2, AIROBOT2, or AUTOFEED. These robotic systems consist of a sample storage unit with magazines and a transfer clamp which takes the fibre from the storage unit and delivers it to the FAVIMAT+ testing section.

Compared to conventional single-fibre testing equipment using separate, manually operated test stations, the FAVIMAT+ with ROBOT2 or AIROBOT2 reduces labour time by as much as 95 percent, in case of AUTOFEED by up to 98 percent, depending on the type of tests involved.

For FAVIMAT+ various clamp types and load cells are available to cover a wide range of fibre materials including Aramid, UHMWPE, glass and carbon fibres. In addition, the FAVIMAT+ can be equipped with short-fibre clamps to manually test fibres down to 3 mm cut length.

System components

Test section:

- One pair of single-fibre clamps, also suited for

other narrow test specimen; - Continuously adjustable gauge length

0 – 100 mm; - Draw-off clamp speed 0.1 – 100 mm/min,

return speed 300 mm/min,

max. travel of draw-off clamp 100 mm; - Additional vertically movable measuring head

that automatically swings into the test section,

comprising two measuring systems for the

measurement of linear density and the

determination of crimp geometry.

Measuring systems:

- Force measuring device, resolution 0.0001 cN,

measuring range 220 cN, other ranges

available on request; - Elongation measuring device,

resolution 0.1 μm; - Linear-density measuring system with acoustic

initiation of the fibre vibration and opto-electronic

recording of the resonance frequency; - Opto-electronic measuring system for digital

recording of the fibre geometry.

(AI)ROBOT2:

- Fibre sample storage unit for a maximum of 20

magazines, each with a capacity of 25 single

fibres; - Transfer clamp (AI)ROBOT2 to FAVIMAT+;

- Loading unit for fibre introduction into the

magazine with pre-tensioning weights (ROBOT2)

or pneumatics (AIROBOT2).

TESTCONTROL:

- PC system for controlling the test processes

and for the evaluation of the measured data,

connected via USB interface; - Input of all parameters for testing and measureddata evaluation on the PC, saving of selected

parameter sets of test conditions under

code words; - PC for easy integration within any network type.

Further technical data

Mains supply:

- 220 V, 50 (60) Hz, current requirement

approx. 1.5 A. - Compressed-air supply:

6 bar, 10 l/min., with (AI)ROBOT2 50 l/min.

Lacquer finish:

- RAL 9006/5002.

Dimensions, weight:

- Height 600 mm, width 600 mm, depth 540 mm,

approx. 85 kg (FAVIMAT+); - Height 1125 mm, width 880 mm,

depth 600 mm, approx. 90 kg (ROBOT2).

Technical contents can be subject to changes by Textechno.

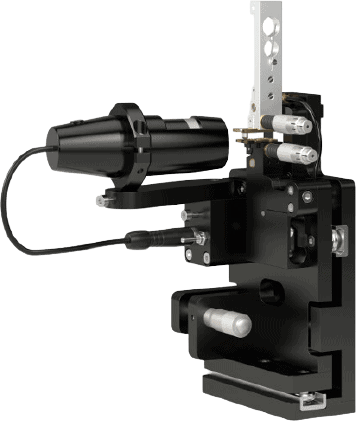

Pull-out Device

The pull-out testing device is easy to install and operate in the FAVIMAT+. A microscopic camera facilitates the adjustment of the clamps as close as possible to the matrix surface with perfect alignment. The direct clamping of the fibre makes the pull-out test fast and efficient – no need for glues and tedious handling.

When the fibre is clamped, the FAVIMAT+ automatically starts the pull-out test and records the force/displacement-curve.

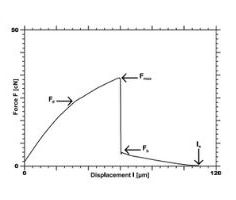

From the force/displacement-curve the system determines all relevant parameters:

- maximum force (Fmax)

- frictional force (Fb)

- debonding force (Fd)

- actual embedding length (le).

Based on these measured values the following quantities are calculated:

The apparent interfacial shear strength 𝛕𝒂𝒑𝒑 is based on the maximum force Fmax.

It is sufficient for a qualitative estimation and a simple discrimination of different fiber-matrix adhesion types. After the debonding of the fibre from the matrix, no bondings are left.

The fiber will be completely pulled out and only friction, expressed by the interfacial frictional stress 𝛕𝒇, will occur.

The local interfacial shear strength 𝛕𝒅 is based on the debonding force Fd. It describes the absolute measure of the fibre-to-matrix adhesion, independent from friction and corrected for deformation of fibre and matrix during the pull-out test.

The critical interfacial energy release rate 𝑮𝒊𝒄 describes the energy required to debond the fibre per unit contact area. It is an alternative to the strain-based paramater 𝛕𝒅.

With the integration of the pull-out device into Textechno’s FAVIMAT+, the complete system allows for an easy and precise determination of linear density and cross section as well as modulus, breaking strength and elongation on top of the fibre-matrix-adhesion.

Bending-Abrasion and Cyclic Stress Tester for Fibres and Yarns

FIBRESTRESS

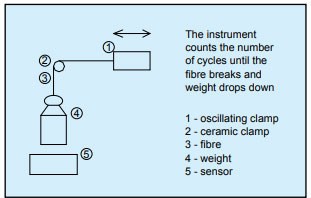

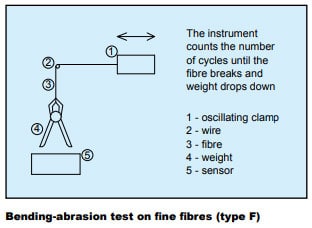

During the fibre bending-abrasion test, the fibre sample is cycled back and forth over a wire or thin pin under given tension and defined angle, e.g. 90°. In this test, the number of cycles up to fibre breakage is the measured variable. Concerning fibres for apparel textiles, the test provides a measure for the tendency to pilling of the wovenor knitted fabric: The smaller the cycle number to break occurrence, the lower is the tendency to pilling, since the pills that develop during textile wear would be shed within a short period.

With this test, for example, Polyester fibres that show little or no pilling have a life span of less than 1000 load cycles, whereas fibres with poor pilling characteristics can reach up to 100 000 cycles.

The opposite is desired for fibres used for carpets:

Fibres for carpet piles must be highly resistant to bending stresses in order to avoid premature breakage during heavy wear of the carpet. The bending-abrasion test is also suitable for staple fibre yarns concerning the stability of their structure or resistance to stress during subsequent processing, e.g. for warp yarn in weaving.

With flax fibres, the fibres increasingly divide into small single fibrils when subjected to the bending-abrasion test, which provides information concerning processing properties.

Finally, in the area of hair care products, conclusions can be drawn regarding the influence of the treatment media concerning hair characteristics, such as elasticity or brittleness, by subjecting the treated human hair to the bending-abrasion test and analysing the results.

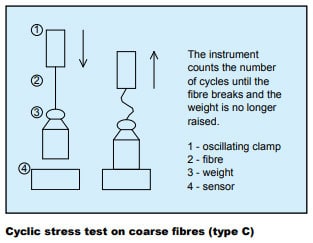

A further test method in addition to the bendingabrasion test, which is also cyclic, is the cyclic stress test. Here, the fibre or yarn is subjected to an alternating change between tension and full relaxation. The measured variable is again the number of load cycles up to break occurrence. Such cyclic stress tests also supply valuable information regarding the fibre or yarn properties during processing, performance characteristics, e.g. for carpets, or the effects of special treatments in the case of human hair.

FIBRESTRESS Type F

This equipment has been designed for bendingabrasion tests on fibres with a linear density within the range of 0.3 – 20 dtex. For the test, one of the fibre ends is held by a clamp and the other end loaded with a pre-tensioning weight. The fibre is bent at a 90° or 110° angle around a wire, which brings about the abrasion stress.

The clamp cycles in a horizontal direction, pulling the fibre backwards and forwards over the wire.

A sensor registers the occurrence of fibre breakage, and the appropriate cycle number count up to that moment is recorded. The equipment features a clamping strip with 25 positions for the simultaneous testing of 25 fibres.

FIBRESTRESS Type C

This equipment uses an identical method as the Type F for bending-abrasion tests on fibres with a high linear density and yarn segments within the range of 3 – 300 dtex. Due to the higher sample count, the equipment has heavier pre-tensioning weights that are guided within vertical channels. If necessary, the weights can be secured against any tendency to self-twist.

In addition to the bending-abrasion test, the FIBRESTRESS Type C can also be used to carry out cyclic stress tests. Here, the reciprocating arrangement of the clamping strip is converted from its position of horizontal movement into a position with vertical motion.

The fibre length must be measured in such a way that, with each downward movement of the clamp, the weight comes into contact with the sensor where upon the fibre is relaxed. If fibre breakage occurs, the weight is no longer raised during the following upward movement of the clamp and the cycle number is recorded. As an option, there is the additional possibility of recording any lengthening of the fibres during the test as a function of the cycle number

CYCLIC STRESS TEST

Technical Data

Sample holder:

- Clamping strip with 25 positions, reciprocating movement, either horizontal or vertical plane

(only Type C and C/ H).

Cycle frequency of clamping strip movement:

- 0 – 4 Hz (0 – 240 strokes per minute).

Wrap element for the bending-abrasion test:

- Wire diameter 0.02 – 0.5 mm, other diameters on request.

Bending angle for the bending-abrasion test:

- Adjustable, either 90° or 110°, other angles on request.

Tensioning weights:

- 70 mg – 10 g (Type F),

- 6 g – 70 g (Type C, C/ H),

- other weights on request.

TESTCONTROL:

PC system for controlling the test process and for the evaluation of the measured data, connected via serial interface.

Further technical data

Dimensions, weight:

- Height 350 / 650 mm, width 640 mm, depth 380 mm, approx. 40 kg.

Technical contents can be subject to changes by Textechno.

FIBRESTRESS Type C/H

The construction of this model for the testing of human hair is mainly identical to the FIBRESTRESS Type C. Here, the ends of the hair segments to be tested are fitted with clamping tubes, which are fastened into the clamps of the tester and to the tensioning weights. This eases treatment of the Bending-abrasion test on coarse fibres (type C) test samples with liquid media prior to the testing.