The performance of composite materials strongly depends on the adhesion of the fibres to the matrix.

In order to make a versatile and reproducible single-fibre pull-out test available to institutes and industrial customers world-wide, Textechno have developed the FIMATEST system together with the Leibniz Institute of Polymer research Dresden (IPF) and the Bremen Fibre Institute (FIBRE).

Fibre-Matrix Adhesion Tester FIMATEST

The performance of composite materials strongly depends on the adhesion of the fibres to the matrix. On the microscopic level different test procedures have been established in various research institutes, however, most results are not comparable, since none of these tests are standardized or commercially available

In order to make a versatile and reproducible single-fibre pull-out test available to institutes and industrial customers world-wide, Textechno, leading experts in the field of fibre testing, has developed a suitable system together with the Leibniz Institute of Polymer research Dresden (IPF) and the Faserinstitut Bremen (FIBRE). While the IPF has long-standing competence and experience in the field of fibre-to-matrix adhesion, FIBRE has contributed by their experience in image analysis for automating the embedding process.

The system consists of two devices: the partially automated embedding station FIMABOND, which is suited for all kind of reinforcement fibres as well as for thermoset, thermoplastic or mineral matrices, and a device that performs high precision pull-out tests as a new accessory to Textechno’s singlefibre linear-density and tensile tester FAVIMAT+.

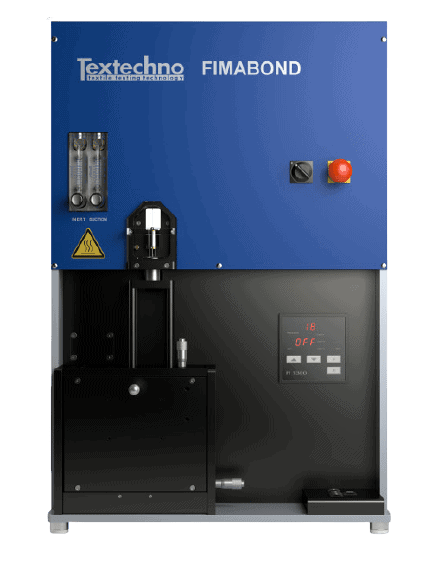

FIMABOND

One of the most critical points to assure reproducible results in a single-fibre pull-out test is the precise embedding of the fibre which is required to avoid shear forces. For this purpose, the fibre has to be embedded exactly in the center of the matrix droplet.

This critical adjustment is perfectly performed with the FIMABOND embedding station.

FIMABOND features freely programmable temperature profiles up to 400 °C and embedding under inert gas. Well suited for both, thermoplastic and thermoset matrices.

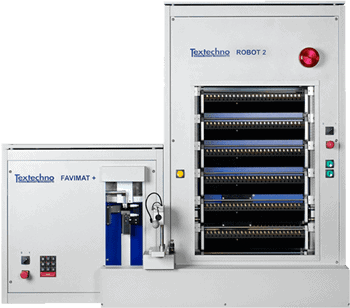

Automatic Single-Fibre Test System FAVIMAT+

FAVIMAT+ is worldwide the first and only single fibre tester which combines six test methods in one instrument, for the determination of the following fibre properties:

- Linear density

- Tensile properties

- Mechanical crimp properties (percent crimp, crimp removal force and crimp stability)

- Geometrical crimp structure

- Fibre-to-metal friction

- Bending stiffness

Operation of the FAVIMAT+ can be fully automated by means of the optional infeed systems ROBOT2, AIROBOT2, or AUTOFEED. These robotic systems consist of a sample storage unit with magazines and a transfer clamp which takes the fibre from the storage unit and delivers it to the FAVIMAT+ testing section.

Compared to conventional single-fibre testing equipment using separate, manually operated test stations, the FAVIMAT+ with ROBOT2 or AIROBOT2 reduces labour time by as much as 95 percent, in case of AUTOFEED by up to 98 percent, depending on the type of tests involved.

For FAVIMAT+ various clamp types and load cells are available to cover a wide range of fibre materials including Aramid, UHMWPE, glass and carbon fibres. In addition, the FAVIMAT+ can be equipped with short-fibre clamps to manually test fibres down to 3 mm cut length.

- Mains supply: 230 V, 50 (60) Hz;

- Inert gas (optional): depending on matrix;

- Compressed air: 5 bar

- Lacquer finish: RAL 9006/5002;

- Dimensions: height 670 mm, width 480 mm, depth 285 mm;

- Weight: approx. 35 kg;

The above technical contents can be subject to changes by Textechno.

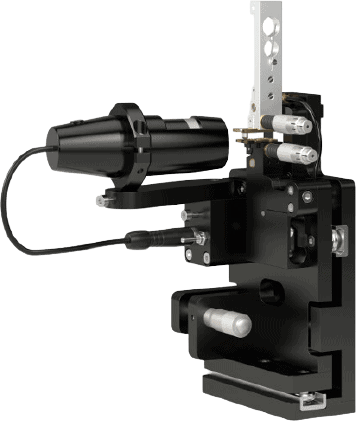

Pull-out Device

The pull-out testing device is easy to install and operate in the FAVIMAT+. A microscopic camera facilitates the adjustment of the clamps as close as possible to the matrix surface with perfect alignment. The direct clamping of the fibre makes the pull-out test fast and efficient – no need for glues and tedious handling.

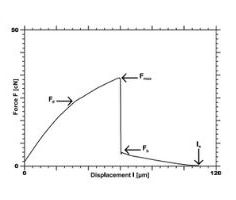

When the fibre is clamped, the FAVIMAT+ automatically starts the pull-out test and records the force/displacement-curve.

From the force/displacement-curve the system determines all relevant parameters:

- maximum force (Fmax)

- frictional force (Fb)

- debonding force (Fd)

- actual embedding length (le).

Based on these measured values the following quantities are calculated:

The apparent interfacial shear strength 𝛕𝒂𝒑𝒑 is based on the maximum force Fmax.

It is sufficient for a qualitative estimation and a simple discrimination of different fiber-matrix adhesion types. After the debonding of the fibre from the matrix, no bondings are left.

The fiber will be completely pulled out and only friction, expressed by the interfacial frictional stress 𝛕𝒇, will occur.

The local interfacial shear strength 𝛕𝒅 is based on the debonding force Fd. It describes the absolute measure of the fibre-to-matrix adhesion, independent from friction and corrected for deformation of fibre and matrix during the pull-out test.

The critical interfacial energy release rate 𝑮𝒊𝒄 describes the energy required to debond the fibre per unit contact area. It is an alternative to the strain-based paramater 𝛕𝒅.

With the integration of the pull-out device into Textechno’s FAVIMAT+, the complete system allows for an easy and precise determination of linear density and cross section as well as modulus, breaking strength and elongation on top of the fibre-matrix-adhesion.