The FIBROTEST combines fibre length measurement and fibre strength test on fibre bundles within one instrument. The two measurements are executed in succession on the same sample. After completing these measurements, the sample mass is automatically determined. This enables the calculation of the exact and absolute value of the tenacity.

PT. Kawan Era Baru is the sole distributor in Indonesia for all Textechno’s products.

“Operation of the FIBROTEST does not require calibration cotton and is, therefore, independent of any influences from this side. Nevertheless the system can be calibrated with calibration cotton to duplicate the results from high-volume testers.”

Key fibre characteristics of cotton

Fibre length and breaking strength determine to a large extent the processing of cotton fibres into yarns and the properties of the yarn itself.

Fibre length is usually measured on a bundle of fibres according to the Fibrograph system. This test is based on an optical scanning device and delivers various parameters characterizing the fibre length distribution.

Fibre strength on cotton fibres can be measured on fibre bundles. As the fibre bundle strength depends on the number of fibres in the bundle, precise measurement of tenacity requires measuring of the tensile forces as well as the mass of the fibres between the clamps with high accuracy.

Present testing instruments are either purely manually-operated devices for each of the two test methods, or fully automatic high-volume test stations. The latter employ measuring systems which have to be calibrated using so-called calibration cotton. For this reason all measured results depend on the data of the calibration cotton as specified by its supplier. They are not directly traceable to physical base units.

Operation of the FIBROTEST does not require calibration cotton and is, therefore, independent of any influences from this side. Nevertheless the system can be calibrated with calibration cotton to duplicate the results from high-volume testers.

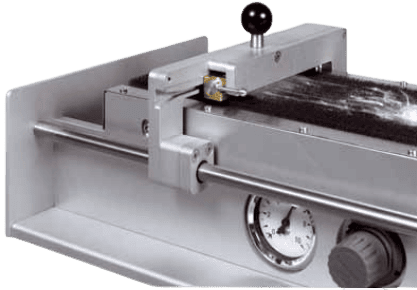

Sample preparation station

Use of the tester is simple and straightforward: The operator prepares the sample with a comb-type sample holder. Unavoidable fibre mass variation along the sample holder is – different from conventional testers – compensated by the FIBROTEST optical system with high lateral resolution. After inserting the sample holder into the tester all test functions are executed in a fully automatic way.

Control of the test process as well as measured data evaluation featuring printout of individual values and their statistical analysis is provided by the Textechno TESTCONTROL system, consisting of a PC and Textechno software.

- Preparation of the fibre bundle with comb-type sample holder;

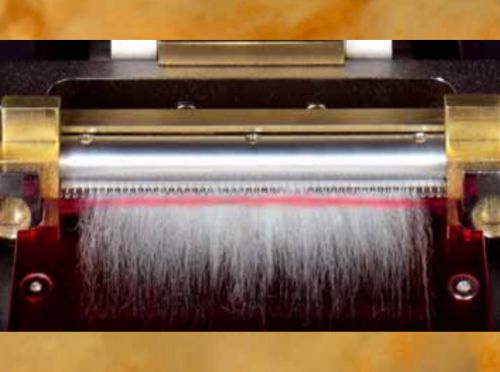

- Optical system with laser light source and line camera to scan the fibre bundle in longitudinal direction, scanning width 60 mm,max. travel 50 mm, 190 mm on request;

- Tensile strength- and elongation measuring system with automatically operated pneumatic clamps, draw-off clamp on motor-driven traversing carriage, strain gauge with force range of 500 N, gauge length 3 … 20 mm, draw-off speed 1 … 1000 mm / min;

- Automatic determination of sample weight between clamps.Preparation of the fibre bundle with comb-type sample holder;

- Optical system with laser light source and line camera to scan the fibre bundle in longitudinal direction, scanning width 60 mm, max. travel 50 mm, 190 mm on request;

- Tensile strength- and elongation measuring system with automatically operated pneumatic clamps, draw-off clamp on motor-driven traversing carriage, strain gauge with force range of 500 N, gauge length 3 … 20 mm, draw-off speed 1 … 1000 mm / min;

- Automatic determination of sample weight between clamps.

- PC system with Microsoft Windows®, connection to FIBROTEST via USB interface;

- Textechno-Software for control of the testing process as well as for evaluation of the measured data;

- Parameters for testing and evaluation can be stored as sets for later usage;

- Easy integration into any network type.

- Mains supply: 230 V, 50 (60) Hz, current requirement approx. 1,6 A

- Compressed-air supply: 6 bar, 50 l/min

- Lacquer finish: RAL 9006/5002

- Dimensions HWD [mm]: 410/700/550

- Weight: approx. 45 kg

The above technical contents can be subject to changes by Textechno.