Parts and Accessories

Slack & Parr

World leading manufacturers of custom precision gear pump solutions

Slack & Parr design and manufacture the most advanced precision gear metering pumps, industrial dosing pumps and hydraulics flow divider solutions. Our unique approach ensures you get the best ‘whole of life product’ return on investment, because every product is designed to your specific environment, application and specifications – then manufactured to order.

Gear Metering Pumps

In these constantly evolving, dynamic times, customers rightly demand highest quality, unrivalled service and complete flexibility from their key partners. Slack & Parr offer this together with a knowledge of gear pumps that can put our customers one step ahead of their rivals. Slack & Parr have been responsible for several major innovations in man made fibre spinning. The development and successful introduction of planetary polymer gear pumps and spin finish metering pumps are significant examples, and we are continually introducing improvements into our standard products to increase their quality and cost effectiveness. Certain applications require specialised designs, and in such cases we are pleased to offer customised solutions to meet our customers’ requirements.

Acetate & Viscose Pumps

Description

0.142 to 30cc/rev. outlet options to suit installation

Trunnion mounted or foot mounted options available to suit all customers installations.

General Operating Parameters:

- Viscosity 100 to 1200 poise

- Speed 10 to 30 r.p.m.

- Inlet Pressure 1 to 15 bar

- Outlet Pressure 20 to 70 bar

- Temperature 30 to 50° C

Acrylic Pumps & Drives

Description

0.15 to 6000cc/rev. outlet options to suit installation.

We can offer an entire range of Acrylic solutions, from small laboratory test pumps, up to large capacity transfer and slurry pumps.

General Operating Parameters:

- Viscosity 200 to 1000 poise

- Speed 10 to 60 r.p.m.

- Inlet Pressure 3 to 10 bar

- Outlet Pressure 10 to 30 bar

- Temperature 80 to 100° C

Aramid Fibre Pumps

Description

0.5 to 2000cc/rev. outlet options to suit installation.

Slack & Parr have unrivalled knowledge of the Aramid spinning process, and of the pump and materials technology needed to best meet the highly advanced performance that this process demands.

Slack & Parr require detailed operating parameters to specify optimum product.

Booster, Oligomer & Transfer

Description

20 to 3000cc/rev. outlet options to suit installation.

Higher volume Transfer pumps for all fluids, Polymers and Oligomers.

Available either as bare shaft pumps, with heating and insulation options, or as a completely engineered unit with drive motor, gearbox and coupling.

Slack & Parr require detailed operating parameters to specify optimum product.

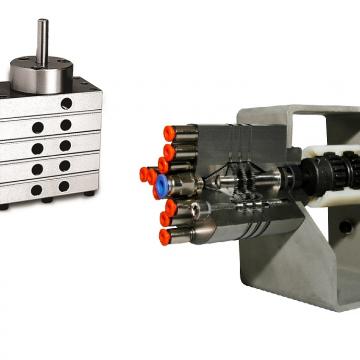

Spin Finish Pumps

Description

0.03 to 3cc/rev. 2, 4, 6, 8, 10, 12, 16, 20, 24, 32 outlets.

The new SPS range has been released building on the quality foundations of our traditional rectangular models and our SPZ range.

Below is a summary of the main improvements;

- Hub Seal design for accurate alignment

- Lubricated front bearing

- Enhanced mis-alignment compensation features

- Accurate metering at low speeds

- Prolonged life

- Very compact design

General Operating Parameters:

- Viscosity 1 to 300 centipoise

- Speed 5 to 100 r.p.m.

- Differential Pressure 0.1 to 0.3 Metre H2O typical

Polymer Metering Pumps

Description

CONVENTIONAL POLYMER METERING PUMPS

0.15 to 30cc/rev. 1, 2, 3, 4 outlets

Traditional designs of rectangular metering pumps available for all customer’s existing plants, either for replacement or expansions.

All Slack & Parr’s latest design features can be easily incorporated into these more traditional designs.

General Operating Parameters:

- Viscosity 300 to 10,000 poise

- Speed 10 to 60 r.p.m.

- Inlet Pressure 10 to 100 bar

- Outlet Pressure 100 to 500 bar

- Temperature Up to 350° C

Planetary Pumps

Description

0.15 to 30cc/rev. 3, 4, 5, 6, 8, 10, 12 outlets

Modern designs of planetary metering pumps, using the very best materials available, tailored to each customer’s individual needs, and including Slack & Parr’s very specific lubrication and pressure controlling features for maximum pump life and performance.

General Operating Parameters:

- Viscosity 300 to 10,000 poise

- Speed 3 to 40 r.p.m

- Inlet Pressure 10 to 100 bar

- Outlet Pressure 100 to 500 bar

- Temperature Up to 350° C

Chemical Pumps

Description

Outlet options to suit installation.

Slack & Parr offer pumps to operate in the most arduous chemical applications.

Choice of material is critical to ensuring accurate metering in corrosive and abrasive environments.

The use of components made from Zirconia ceramic has been especially successful in the most severe operating conditions.

Slack & Parr require detailed operating parameters to specify optimum product.

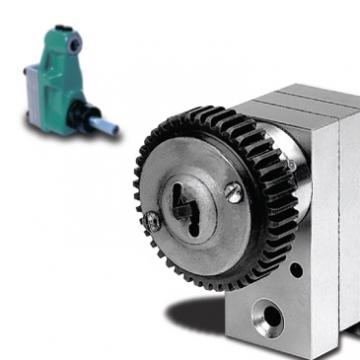

Hydraulics

We design and manufacture a standard range of high accuracy rotary Flow Dividers which contain ground gears and lapped finishes with emphasis on accurate division and high pressure rating.

Special applications for example, Stainless Steel Flow dividers, can be manufactured for highly corrosive environments.

Small quantities and specific designs can be accomodated.

Flow Divider FDL

Description

Rotary Geared Flow Divider FDL

These Flow dividers are our large capacity flow dividers. The capacities are from 12cc/rev through to 30cc/rev.

Flow Divider FDR

Description

Rotary Geared Flow Divider FDR

These Flow dividers are our latest round design. The capacities are from 2cc/rev through to 9cc/rev.

Stainless Steel Flow Divider FDR

Description

Rotary Geared Flow Divider FDR (Stainless Steel)

Flow Meter FML

Description

Positive Displacement Flow Meter Type FML, ranges between 3 and 90 Litres

Industrial Pumps

Capacities from 0.15cc/rev to 1000cc/rev. outlet options to suit installation.

Fluids including oils, paints, cosmetics, adhesives and water can all be accurately metered either using one of our off the shelf industrial metering or dosing pumps alternatively using a solution specifically designed for the application.

Acids

A range of pumps engineered using special material combinations and sealing methods to enable them to perform in the most agressive of environments. We have proven experience handling many different acids, some of which include: Formic Acid, Nitric Acid, Polyactic Acid, Ethoxylated Fatty Acid, Hydrochloric Acid, Sulphuric Acid

Additives

Satisfying the requirement to introduce metered quantities of additives into a process we work with several global customers across a diverse range of applications from Chocolate to Acrylic fibre. We also include a range of pumps for Pigmented Slurry to add desirable properties such a surface finish or colour to fibre and plastic products.

Adhesives

We have many years of experience metering adhesives around the world and are the preferred choice in the USA for a major machine manufacturer. We include in this a range of pumps suitable for Isocyanate and Polyol.

Fuel

We have decades of experience supplying fuel pumps for accurate fuel delivery in Classic racing cars and boats.

Foods

With many years of experience metering chocolate for a global brand leader, we are able to offer pump solutions meeting European Standard, our solutions have been applied with, but not limited to: Pasta Dough, Food Skins, Sauces, Syrups, Cocoa butter, Liquorice

Ink

We offer gear pump solutions to deliver metered quantities of Alkaline dyes and inks to the print industry.

Oils

We have designed pumps to perform across the wide range of viscosities that are needed to enable us to offer pump solutions in this diverse category, some of which include: Heavy Oil, Bitumen, Diesel Oil, Linseed Oil, Greases, Emulsions

Paint

With many applications to our credit, we have once again proven our metering accuracy in several global industries that include market leaders in their industries. Our pumps are engineered with flushing ports for ease of cleaning and colour change.

Peek

Polyetheretherketone a high performance engineered colourless polymer used in engineering applications. We have several designs that are our customers first choice in several countries around the world.

Resins

Our pumps are engineered to meter these viscose products and we have many successful relationships with several major companies manufacturing products ranging from Sports shoes to Tyre Cord.

Sealent

With applications including the automotive industry, we are the trusted choice to replace existing metering pumps on OEM’s at major car manufacturers in the UK.

Water

The viscosity and corrosive nature of water present challenges for Gear Metering pumps that we have overcome with selective material choices, coatings, sealing options and specialised bearings depending on required pump speed and pressures.

If you need a water metering pump or a water dosing pump, our range of specilist water pumps have been designed just for this application. With very small capacities we can accuratly meter or dose water (and other low viscosity fluids) to a laminar flow (pulsless) to very small flow rates.