Parts and Accessories

BINSFELD ENGINEERING INC.

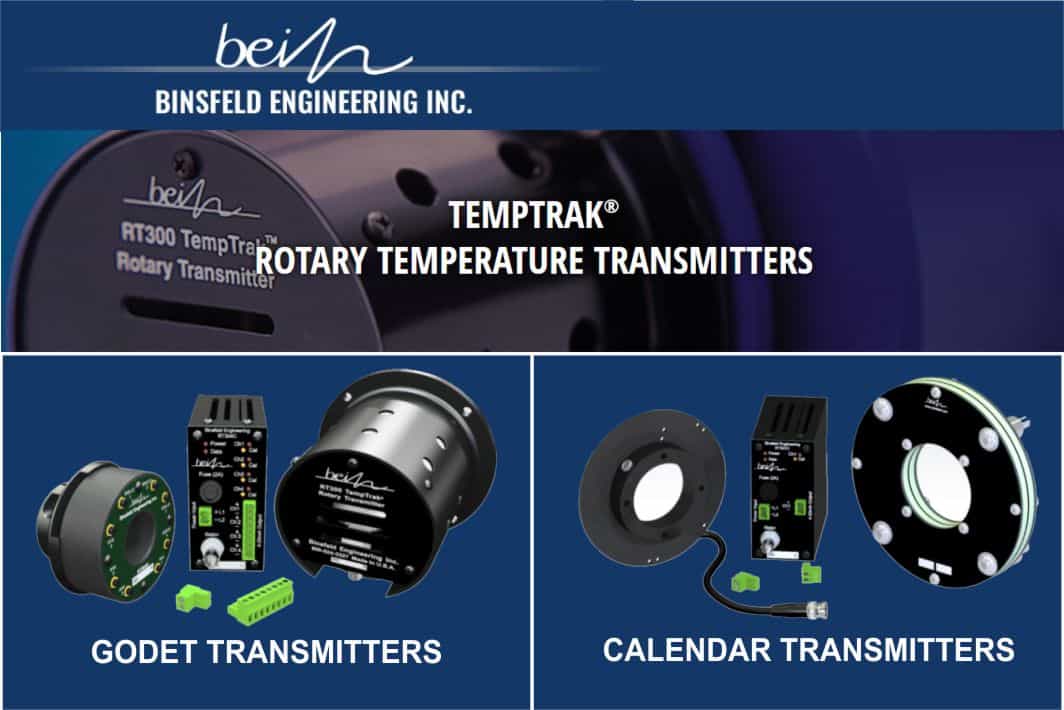

TEMPTRAK®

Binsfeld’s Rotary Temperature Transmitter Systems provide accurate and reliable temperature control on heated godets and calendars. We also offer design and OEM services.

GODET TRANSMITTERS

IMPROVED GODET PERFORMANCE YIELDS SUPERIOR FIBER

RT501I-IOL Series

An industrial interface that functions with a variety of Binsfeld Temperature Transmitters. This interface allows Temperature Transmitters to be connected to common industrial field bus. These field buses include, but are not limited to PROFINET, EtherNet/IP, and Modbus TCP/IP. Use with commercially available off-the-shelf IO-Link Masters is required.

- Digital circuitry from sensor input to signal output

RT416-PB Series

A multi-channel wireless temperature measurement system designed as an upgrade for CAN bus systems to monitor and control temperature on heated godet roll shells on filament spinning machines. Digital circuitry in the rotating transmitter and the stationary receiver are immune to electrical noise and drift. Generous 5 mm clearance between the rotating and stationary parts eliminate rubbing or impacting – a common failure cause in other designs. Error detection modes protect heater from damage and expedite troubleshooting in the event of a sensor or other failure. The system features Profibus DP digital communication. It consists of three main components: Controller, Rotating Module with mounting base, and Stationary Module.

RT406 Series

A multi-channel temperature measurement system designed to monitor and control temperature on heated godet roll shells. Digital circuitry in the rotating transmitter and the stationary receiver are immune to electrical noise and drift. Generous 5 mm clearance between the rotating and stationary parts eliminate rubbing or impacting – a common failure cause in other designs. Error detection modes protect heater from damage and expedite troubleshooting in the event of a sensor or other failure

RT381 Series

A one-channel temperature measurement system designed as an upgrade for Fuji Electric FTM 1AA02-Z (RT381) ; Teijin-Seiki STA (RT381-SP) and similar transmitters to monitor and control temperature on heated godet roll shells on filament spinning machines. The system features generous 10 MM clearance between the rotating and stationary parts which eliminates damage due to impact and rubbing. TempTrak® data communications technology is unaffected by dust or debris. Digital circuitry in the rotating transmitter and the stationary receiver are immune to electrical noise and drift. Fault detection modes protect heater from damage and expedite troubleshooting in the event of a sensor failure.

RT376 Series

A six-channel wireless temperature measurement system designed to monitor temperature on heated godet roll shells. It can be used to replace a Dienes AIO (All-in-One) transmitter. The system features a linear 4‑20 mA output from the controller interface for use with standard process controllers. Error detection modes protect the heater from damage and expedite troubleshooting in the event of a sensor or other failure. Digital circuitry from sensor input to signal output and generous clearance between the rotating and stationary components make the RT376 a robust and reliable element in the temperature feedback loop.

RT362 Series

A two-channel wireless temperature measurement system designed to monitor temperature on heated godet roll shells. The system features Dienes-compatible output signals for temperature control on Trützschler (SwissTex / Rieter) machines. Error detection modes protect the heater from damage and expedite troubleshooting in the event of a sensor or other failure. Digital circuitry from sensor input to signal output and generous clearance between the rotating and stationary components make the RT362 a robust and reliable element in the temperature feedback loop.

RT360 Series

A versatile multi-channel temperature measurement system designed to operate with a variety of machine configurations and control systems. The RT360 offers a selection of output signals including frequency (for Dienes process controllers); voltage; 4-20 mA current (for use with standard process control systems), and digital data stream. Generous 5 mm clearance between the rotating and stationary parts eliminate rubbing or impacting – a common failure cause in other designs. Digital circuitry in the rotating transmitter and the stationary receiver are immune to electrical noise and drift. Error detection modes protect heater from damage and expedite troubleshooting in the event of a sensor or other failure. Multiple mechanical configurations are available to fit most machines.

RT351 Series

A single-channel temperature measurement system that features Dienes-compatible output signals for temperature and speed. The RT351 also features a linear 4-20 mA output for use with standard process control systems. Digital circuitry in the rotating transmitter and the stationary receiver are immune to electrical noise and drift. Generous 5 mm clearance between the rotating and stationary parts eliminate rubbing or impacting – a common failure cause in other designs. Error detection modes protect heater from damage and expedite troubleshooting in the event of a sensor or other failure. Multiple mechanical configurations are available to fit most machines.

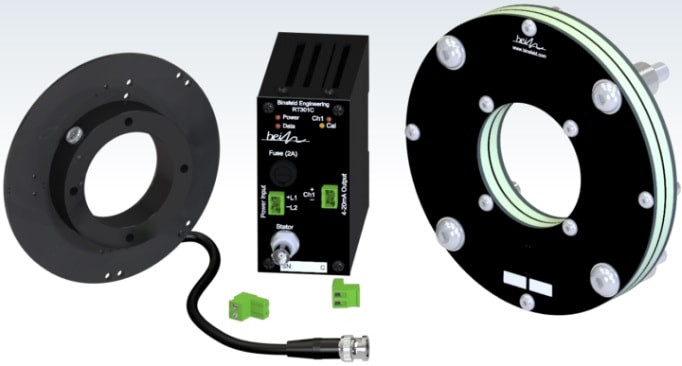

CALENDAR TRANSMITTERS

The RT310 Series Transmitter is an extremely reliable multi-channel temperature measurement system for the calendar industry. The digital transmitter circuit and digital controller interface circuit are immune to electrical noise and drift. Generous 9 mm clearance between the rotating and stationary parts eliminate rubbing and impacting – a cause of failure in other designs. The stationary electronics are housed in a small DIN-rail mount enclosure to remove them from the harsh calendering environment. Models are available to accommodate from one to four RTD signals in a variety of mechanical configurations to fit most machines.

- RT311 – One-Zone Temperature Transmitters

- RT312 – Two-Zone Temperature Transmitters

- RT313 – Three-Zone Temperature Transmitters

- RT314 – Four-Zone Temperature Transmitters

FEATURES & BENEFITS

Accurate – Within ± 0.3% across entire sensing range.

Robust – Fully encapsulated rotating electronics with generous clearance between rotor and stator.

Flexible – Programmable for different sensors and different outputs.

Versatile – Easily configured to fit most roll / calendar shafts.

DIN-Rail Mount – Controller Interface installs easily in instrumentation cabinet.

Digital Circuitry – Digital rotor and stationary circuitry immune to noise and drift.

Multiplexed Channels – One to four channel systems available.

Intelligent – Protects heater if sensor, transmitter or cable malfunctions.

High Speed – Designed to operate up to 5,000 RPM.

Product Support – Backed by BEI’s reputation for the strongest customer support in the industry and a full two-year warranty.

SPECIFICATIONS

The RT310 series utilizes a digital transmitter circuit and digital controller interface circuit. Its inductive power and data transfer scheme is completely noncontact. Components are completely interchangeable and will handshake and adjust power levels as required. Different models are available to accommodate from one to four RTD signals.

NUMBER OF SENSORS:

Models available for 1-4 sensors

SENSOR INPUT:

PT100 RTD (100Ω at 0°C, α =.00385, two wire) standard (other configurations available including nonstandard RTDs)

SENSOR RANGE:

0° to 300°C standard (other configurations available)

SENSOR CONNECTION:

M3-0.5 screw terminals with socket-head cap screws

(designed for #4 ring terminals on customer sensor leads)

OUTPUT CONNECTION:

Quick connect screw terminal block

OUTPUT SIGNAL:

Discrete 4-20 mA current source (each channel)

ACCURACY:

±0.3% span over operating range

AMBIENT TEMPERATURE:

Rotating Unit: 0°C – 100°C

Stationary Housing: 0°C – 100°C

Controller Interface: 0°C – 85°C

Humidity: 0-90% RH, non-condensing

POWER INPUT:

22-35 VDC or 17-27 VAC; 2A max, 0.5A nominal

ROTOR SPEED:

5,000 RPM maximum