Machineries

Tonghe

Textile Machinery Components

Precision manufacturing line, metal plate intelligent manufacturing line, intelligent spraying line, new type spinning frame assembling line, roller intelligent manufacturing line, and etc.

Tonghe Products

Bottom Rollers

New Generation Super High Precision Non-mechanical Wave Bottom Roller.

World’s top imported whole processing equipments. Most reasonable roller surface groove geometry, most accurate machining accuracy, best surface treatment, best raw materials in the world. Most ideal heat treatment hardness, optimum roundness of roller, most advanced detection technology

Quality Commitment

High quality raw material, bending strength increased by 9.1%. Easy installation without shim. No mechanical wave rate ≥98%. Consistent surface color, smooth without any burs and waste fiber adhesion. 20 years of service life

Tonghe Textile Machine

Series of Roving Frames, TH598J Intelligent E-Drafting Super Long Ring Spinning Frame, and THKQ Type Bobbin Transportation System.

Pendulum Arms

International renowned steel with first-class processing technology that has integral design for Fewer components. Front, middle and rear 26mm wide grip, structure 64 possible load setups grade regulating. Consistent surface color, smooth without any burs. Lifting angle 50/75 degrees, easy to operate. Suitable for a wide range spinning, meet with different varieties of technology.

Quality Commitment

Solid and reliable structure, Never wear out of parts, Never go away of the pressure, Never change of the parallelism, Never rust of parts, 20 years of service life.

Let’s discuss your textile machineries needs with us.

Compact

Four-bottom roller negative-pressure compact spinning and Perforated Metal Cylinders Type Compact Spinning.

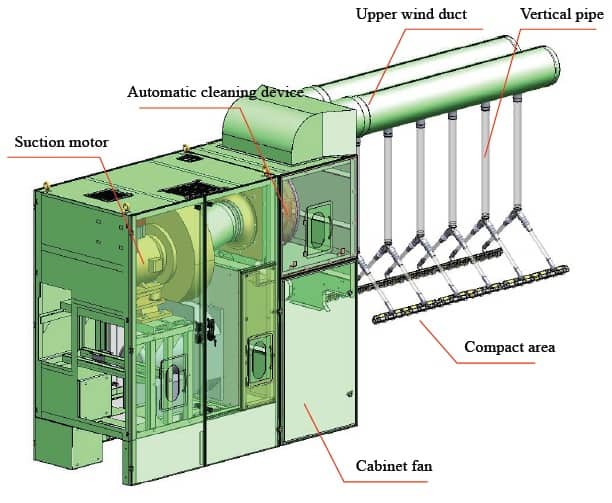

Four-bottom roller negative-pressure compact spinning

- Adjustable negative pressure system

- Automatic waste cleaning device

- Stainless steel tension bracket

- Integral E-tube

- Washable mesh aprons

Adjustable negative pressure system

- Variable section negative pressure duct, reduce the negative pressure difference

- Inverter control negative pressure to save energy consumption

- Negative pressure could be adjusted according to the spinning variety

- Rare-earth permanent magnet motors reduce energy consumption

- Upper wind duct, no affect the line of sight and operation.

Automatic waste cleaning device

- Reduce labor intensity

- Reduce employment

- Negative pressure is stable and consistent

- Yarn index stability.

Stainless steel tension bracket

- Never rust

- Never wear out

- Never deformation

- Never aging

- Reversible structure

- Easy to disassemble and install mesh aprons

- Prevent the mesh aprons from running off track

- Yarn quality stabilization.

Integral E-tube

- Good rigidity, good consistency

- Open mounting with small bottom roller

- Do not accumulate waste easily

- Little CV difference between spindles

- Double suction design

- More uniform negative pressure

- Yarn quality stabilization

Washable mesh aprons

- High quality imported carbon coated wire

- Imported loom weaving, good consistency

- Cleaning cycle can last up to 20 days

- Service life up to 9 months

Perforated Metal Cylinders Type Compact Spinning

- Perforated Metal Cylinders

- No mesh aprons consumption

- No carrier gear

- Special surface treatment

- No fibers on the surface

- Yarn quality stabilization

- Independent property rights of suction unit

- Streamlined design

- Airless vortex

- Little negative pressure loss

- Good compact result

- No block of fibers

Ring Frame

New Generation TONGHE Ring frame TH 698 Type with Maximum Speed 28,000

Roving Frame

Innovative features of THC2015 High end Intelligent roving frame

- Fashion appearance

- High speed and high yield

- Save labor and time

- Wide range of spinning

- Easy installation

- Easy operation

- Zero defect yarn

- Stable and reliable

- Low failure rate

- Information network

- High-end configuration

- High self-making ratio

- Precision manufacturing

- Fine assembly

Spinning Frame

Innovative features of TH598J Intelligent E-drafting Super long ring spinning frame

- Fashion appearance

- High speed and high yield

- Save labor and time

- Wide range of spinning

- Easy installation

- Easy operation

- Zero defect yarn

- Stable and reliable

- Low failure rate

- Information network

- High-end configuration

- High self-making ratio

- Precision manufacturing

- Fine assembly

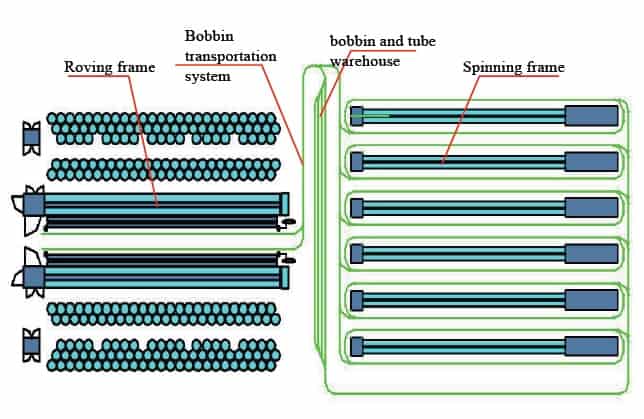

Bobbin Transportation

THKQ Type Bobbin Transportation System

System Composition

- Reversing mechanism

- Aluminium alloy rail

- Pulley chain

- Pulley driving device

- Rail dust cleaning device

- Yarn warehouse cleaning system

- Tail yarn cleaning device

System Classification

- Manual bobbin transportation system

- Manual bobbin and tube exchanging

- Manual transportation from full yarn to yarn warehouse

- Manual transportation from tail yarn to yarn warehouse

- Manual tail yarn tube cleaning

System Advantages

- Clear variety management

- Convenient bobbin changing

- Improve management level

- Reduce employment

- Reduce labour intensity

- Personalized design