Machineries

Penguin Engineers

Stretch Wrapping Machine

Model: Inova

Penguin Pallet stretch wrapping machine is an ideal machine for wrapping pallets, including high-cube containers, ready to be exported in containers. Also, the stretch film packing is used for protection against perforation, moisture, protection against corrosion from sea air, dust etc. It is ideal for packing products like textile cone yarn, castings, light & heavy engineering goods, pharmaceutical products, electrical & home appliances, sacks containing grains, chemicals, fertilizers, tins containing, fruit pulp, paint, liquids, lubricants, jumbo bags containing products like: activated carbon, granules, powders etc.

Stretch Wrapping Machine

Model: Inova

There are certain specifications on the penguin machine that the customer can customize:

- Turn table

- High pallet

- RPM

- Tension.

Inova Technical Sepcification

| CAPACITY | Innova |

| Pallets / hour (nos) | 15 – 25 pallets/hour |

| Pallet size (mm) | 1200 L x 1200 W |

| Pallet height | 2600 mm H |

| Weight / pallet | 2000 Kg |

| Turn Table | |

| Diameter | 1650 mm |

| Height (above GL) | 80 mm |

| Speed | 1-10 rpm |

| Maximum stretch | 300% (100% ~ 300% just need setting) |

| Installed power | 1.5 kW |

| Power supply | 220V, Single Phase, 50Hz |

| Shipping details | 1250 kg/4.0m3 |

| Film Details | |

| Material | LLDPE – Stretch Film |

| Film width | 250 to 500 mm |

| Film thickness | 12-35µ (23µ recommended) |

| Core diameter | 76 mm |

| Maximum film diameter | 250 mm |

Stretch Gear Type Can Be Set

- First gear 100%

- Second gear 200%

- Third gear 300%

Only Penguin Engineers Stretch Wrapping Maching that can perform three type of stretch gear type above, you may not find on any other wrapping machine.

Stretch Wrapping Machine

Model: Classic

The Penguin Stretch Wrapping Machine is a fully automatic machine for wrapping pallets using stretch cling film.

This machine ensures stable and moisture-proof wrapping of pallets at minimum cost. Optimum wrapping of pallets using wide range of film material is made possible by the state-of-the-art “Powered Pre-Stretch Unit ” which can stretch the film up to 300% (One meter long becomes 4 meters long). Powered Pre-Stretch unit has a separate motor to stretch the film.

Classic Stretch Wrapping Machines Features

- This simple and sturdy machine can operate continuously under severe industrial environment. The machine can be easily operated by unskilled workers in the packing line as the cycle of operation is completely automated.

- Fully Automatic Machine.

- Variable speed AC motors

- Top, Bottom and Middle reinforcement wrap

- Life lubricated gear boxes

- AC Drives

- PLC

- Stretch % display

- Touch screen HMI

- Wrap tension control dancer

- Automatic operation

- Foldable mast

- Easy threading of stretch film

- Chain cut sensor

- Forklift lifting slots

- Economy in film consumption

- State-of-the art machine

Fabric Roll Wrapping Machine

Stretch wrapping is the most economical way of Roll packing. The Penguin Fabric Roll Stretch Wrapping Machine is the prestigious “Pacmachine” award winner. It is used to pack rolls of many items like denim fabric, carpets, curtain cloth, paper, film etc. Penguin Stretch Wrapping Machine offers the most profitable way to pack your valuable goods by saving in cost of film, labour and power. Penguin machines are from the leaders in stretch wrapping and are in use at various industries

Fabric Roll Wrapping Machine Features

- Highly economical and huge savings over shrink packing/gunny bundles

- Suitable for packing any rolls of Denim Cloth, Curtain Cloth, Carpets, Foam sheets, Upholsteries, Fabrics, Film, Paper etc.

- Occupies less space

- High productivity 30 – 50 rolls/hour

- Tremendous savings in labour, time and money

- Highly durable dust and moisture proof packing

- Powered Pre-Stretch unit to minimize film consumption

- Variable stretch percentage up to 300%

- Adjustable traverse to suit different roll width

- Controlled film tension

- Variable Overlap, Variable End Reinforcements, Variable Stretch Percentage and Variable Roller Speed

- Digital counters for end reinforcement wrap setting, film consumption and stretch percentage display

- Simple to operate, sturdy & safety control panel

- Cradle for easy loading of film

- Easy loading and unloading of Fabric roll and ease of integration into conveyor lines

- High energy saving-more than 90% saving over shrink wrapping

- Minimum service points

- Payback period is only few months

- Excellent after-sales-service support

- 12 months warranty

Technical Specification

|

CAPACITY |

|

|

Rolls/Hour |

20-40 rolls |

|

Weight/ Roll |

400 kgs * |

|

Roll Diameter |

600 mm * |

|

Roll Width |

1900 mm* |

|

Machine |

|

|

Roller Height (above GL)= |

350 mm |

|

Speed |

50 meters/minute |

|

Maximum stretch |

300% |

|

Installed power |

1.5 kW< |

|

Power supply |

220V, Single phase, 50Hz |

|

Film Details |

|

|

Material |

LLDPE – Stretch Film |

|

Film width |

250 to 500 mm |

|

Film thickness |

12-35µ (23µ recommended) |

|

Core diameter |

76 mm |

|

Maximum film diameter |

250 mm |

PENGUIN Hose Machines

Unleash the power of PENGUIN Hose Machines to conquer industry challenges! Engineered for maximum performance and uncompromising reliability, these machines are the ideal partners to meet all your hose-related needs.

With PENGUIN Hose Machines, you not only get a powerful machine but also a loyal companion in tackling every task. Don’t let opportunities pass you by – enhance your productivity and work quality with PENGUIN Hose Machines!

Outstanding Performance

Designed to handle heavy-duty tasks with high speed and exceptional accuracy, PENGUIN Hose Machines ensures peak productivity.

Latest Technology

With advanced technology, PENGUIN Hose Machines make your job easier and more efficient. Save time and energy with cutting-edge features that guarantee precision results.

Penguin Hose Machines

Heavy Duty Braider – Flech X

Hydraulic Hoses

Introducing the PENGUIN Rubber Hose Machine Heavy Duty Braider Flech X – where strength meets precision in hose manufacturing. Engineered for heavy-duty applications, this machine redefines excellence in braiding technology.

Equipped with cutting-edge technology, this machine delivers precise and intricate braiding for rubber hoses, setting a new standard for quality and efficiency.

Elevate your hose manufacturing capabilities with the PENGUIN Rubber Hose Machine Heavy Duty Braider Flech X – where heavy-duty performance meets precision braiding for superior results. Upgrade to excellence in hose manufacturing today!

Feature

- 100% carriers and bobbins included in the machine price and supplied along with machine

- Built-in Haul-off with separate geared motors for each jaw suitable for flexible and rigid hoses

- Latest Technology — No top plate braider

Heavy duty horn gears for high pressure braiding — Tension from 3 to 13 kg / carrier - Acoustic enclosure

Sufficient suction fans for temperature control - Large bobbin capacity upto 9 kg wire / bobbin and 1.25 kg yarn / bobbin — Reduced bobbin change time

- Carriers require rninimum compensation

- Heavy duty deck plates

- Ergonomically designed doors and openings

- Smooth carrier transfer by “carrying type’ horn gears

- Specially crafted heavy duty horn gear and smooth track

- All springs included in the supply of carriers; Clutch springs & Torsion springs

- Hose guides at each braiding point and Haul-off ends

- Suitable for braiding — High tensile brass coated steel wire, Stainless steel wire, Different yarns like Kevlar, Aramid, Nylon, Polyester (Coated and Uncoated)

- Up to 48 carrier braiders for maximum coverage upto 75mm braiding diameter

- Electronic gearing for “On the Go” pitch control

- Independent deck drive motor and control

- Complete Electronic drives, controls, PLC, Touch panel and Pitch control

- Start / Stop / Jog push buttons at convenient places

- Single wire cut, Bobbin empty, Full wire cut sensors included for efficient quality braiding

- Interlock switches for door openings

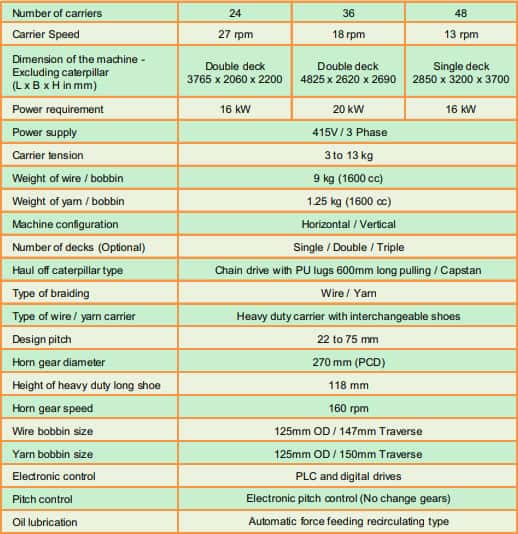

Specification

High Speed Bobbin Winder

Electronic Brake System

Where Precision Meets Performance in High-Speed Wire Winding

Unleash the power of precision and efficiency with our state-of-the-art wire winder model: PHEW-LO12. Designed for unparalleled winding performance, this high-speed bobbin winder is set to redefine your wire winding experience.

Elevate Your Wire Winding Experience with the PHEW-LO12 High-Speed Bobbin Winder!

Feature

Consistent Quality, Unmatched Performance

Say goodbye to inconsistencies in winding with the PHEW-LO12. Boasting modular let-off stations, this winder can be customized to meet your unique requirements. Experience a seamless flow of wire with the constant wire length feature, while the digital tension control system maintains a consistent tension that surpasses industry standards.

No More Wire Crossover Hassles

Bid farewell to wire crossover woes during the reeving process. Our innovative wire clamping tool and wire holding springs work in harmony to ensure a smooth and tangle-free winding experience. Enjoy a hassle-free operation that keeps your production line running smoothly.

Automated Excellence, Operator-Friendly Design

We’ve taken automation to the next level! The entire winding process is automated, with only the loading, attachment, and unloading of the bobbin requiring manual intervention. Safety for the operator is paramount, with parameters governing the winding process pre-loaded for peace of mind. Effortlessly monitor and control the entire process through user-friendly operator control panels and convenient push-button stations on both the winder and the let-off module.

Tailored to Your Needs

Versatility is key, and the PHEW-LO12 understands that. Configure the winder according to your specific needs with ease, thanks to its adaptable design. Whether you’re a seasoned professional or just starting in the industry, this bobbin winder is your ticket to enhanced productivity and consistent results.

Upgrade Your Winding Game Today!

Don’t settle for ordinary when you can have extraordinary. Elevate your wire winding process with the PHEW-LO12 High-Speed Bobbin Winder – where precision meets performance. Upgrade your operations, increase efficiency, and enjoy the reliability that sets industry standards.

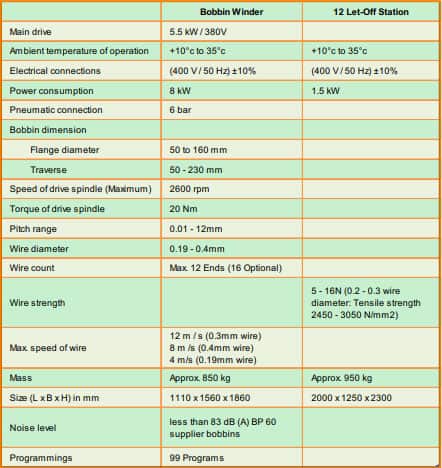

Specification

Hose Wrap / Unwrap System

(For Flexible Mandrels)

Dive into precision with the Penguin Wrapmaster 1000C, your ultimate solution for wrapping and unwrapping cured tape over flexible mandrels effortlessly.

Crafted to perfection, this machine caters to a spectrum of needs, seamlessly accommodating hoses of varying diameters and tape widths.

Elevate your wrapping experience with the Penguin Wrapmaster 1000C. Where precision meets perfection, innovation thrives.

Feature

Control at your Fingertips

Experience unparalleled control with our interactive touch screen interface, putting the power of operation at your fingertips. Navigate through functions effortlessly, ensuring every wrap is executed with utmost precision.

Consistent Performance

Say goodbye to inconsistencies! The Penguin Wrapmaster 1000C guarantees minimal variation in pitch, coupled with controlled wrap and unwrap tension. Each cycle is executed flawlessly, delivering impeccable results every time.

Mechanical Excellence

Engineered with precision, our machine boasts top-notch mechanical subsystems including the wrap head, haul-off caterpillar, brand tape feeder, and doors. Experience reliability like never before with components designed to exceed expectations.

Highlights

- High speed wrapping/ unwrapping of flexible hose upto 1000 rpm

- Controlled wrap tension upto 15 kg Concentric tape wrapping

- Precision wrap with accurate pitch

- Delicate handling of hoses

- User-friendly operator interface with 9″ colour touch screen

- Accurate placement of brand tape

- Adjustable tape tension

- One tape core in operation and three in storage

- Reliable machine for continuous automatic operation

- Release solution collecting arrangement with stainless steel doors

- Electrical and pneumatic brakes for rapid stop Pneumatic door operating system

- Hose guide tubes for wrapping different sizes of hoses

- Automatic hydraulic head movement (optional).

Specification

Hose Knitting Machine

Batch Process

Revolutionize Your Hose Manufacturing!

Join the league of world-class hose manufacturers with Penguin’s cutting-edge Hose Knitting Machine.

Designed to perfection, Penguin Hose Knitting Machine stands tall as the epitome of excellence in the knitted hose industry.

Feature

Key Features:

- Customized Production: Manufacture bent hoses, curved hoses, and hoses of various diameters used in automobiles effortlessly.

- Efficient Operation: Enjoy seamless production with synchronized extruders, ensuring unmatched speed and productivity.

- Adaptable: From 10 mm to 100 mm hose ID, our interchangeable knitting heads cater to diverse manufacturing needs.

- User-Friendly Interface: Navigate operations smoothly with Siemens make PLC & 4″ HMI, allowing for easy control and monitoring.

- Reliable Construction: Built to last, our machine boasts a sturdily built tubular frame structure with stainless steel yarn cover, ensuring longevity and hassle-free operation.

Specification

Technical Specifications:

- Versatile Configuration: Accommodate 2 to 4 feeders based on hose size, with a maximum diameter range of 10 to 100 mm.

- Powerful Performance: Operating on 2.25 kW; 3 Phase 440V for knitting module and 1.1 kW; 3 Phase 440V for caterpillar, ensuring efficient production.

- Precision Stitching: Utilize Groz-Beckert make straight needles for flawless plain stitch.

- Advanced Control: Seamlessly manage line speed, pitch control, and production indications through our intuitive HMI touch screen interface.

Elevate your hose manufacturing process with Penguin’s Hose Knitting Machine – Batch Process. Experience excellence, productivity, and reliability like never before. Contact us today for a seamless transition to superior hose production!